Certified to NSF/ANSI/CAN 61, which now includes NSF/ANSI/CAN 372 Lead Free requirements, Next-Sand™ is a remarkable advance in media filtration technology. Based on a rare natural mineral that is highly processed and refined, Next-Sand‘s unique properties allow it to radically alter the performance and cost of media filtration. The hardness, stability and micro-porous character of Next-Sand makes it a perfect filtration media for virtually every application in the water and wastewater treatment industry.

Next-Sand™

A radically high performance silt, sediment, and turbidity media.

Features

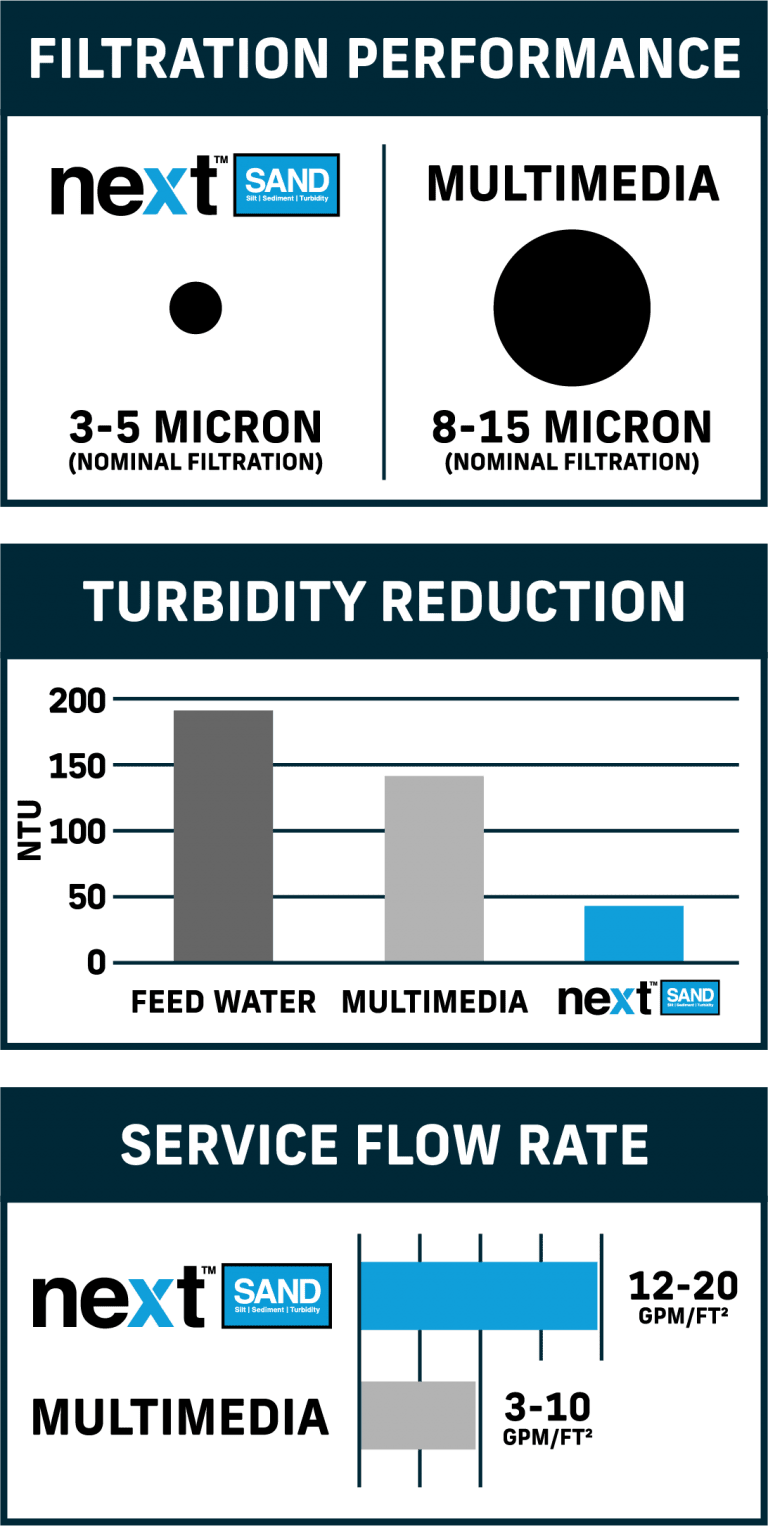

- High Filtration Performance: 3-5 Micron Removal

- High-Capacity Filtration Throughout Bed: >2x The Capacity Of Multimedia Filtration

- High Service Flow: 3-4 Times That Of Multimedia With Superior Filtration

- Long Lasting Media: >5 Years (Not Consumed In The Process)

- Simple, Periodic Backwash Required: Keeps The Media Clean & Operating Efficiently

A revolution in filtration performance & operating economy

Over the past 50 years, improvements in granular media filtration have been achieved by:

- using smaller mesh size sand to remove finer particles,

- by combining sand with garnet or garnet and anthracite (i.e. “multimedia” beds) and

- by improving the fluidics design of beds and vessels.

More recently the traditional sand or multimedia filtration beds have started to make way for zeolite based filtration units. Natural zeolites are a low cost resource recognized for their unique absorption, catalytic, ion exchange, and molecular sieve properties; clinoptilolite is a natural zeolite but it varies greatly in both structure and purity. Next-Sand is a rare high-purity clinoptilolite that offers the very best characteristics for use as water filtration media.

Silt, Sediment & Turbidity

Next-Sand™ offers a single bed media made from high purity clinoptilolite, which delivers superior performance over conventional filter sands or multimedia, and at a lower cost. The material is mined in western USA and then highly processed and graded; the resulting product is hard and stable with a high surface area and micro-porous character in addition to surface micro-crystals making it an ideal filter media.

Next-Sand™ has high filtration performance at <5 micron compared to 12 to 15 micron for multimedia. It also has a higher flow capacity, typically three to four times that of multimedia. This higher flow rate means a greater performance can be achieved from existing vessels when upgraded with Next-Sand, or for new applications smaller filter vessels would be required to achieve the same results.

Filtration through the entire media bed depth provides more than twice the capacity of multimedia filtration. It has a higher dirt holding capacity so requires less frequent backwashing, leading to reduced downtime. Lighter weight and lower volume requirement means lower capital and shipping costs than multimedia and the product also lasts longer. The media isn’t consumed in the filtration process; a simple periodic backwash will keep the media clean and operating efficiently for five years or more.

The unique properties of Next-Sand™ high purity clinoptilolite filter media allow it to radically alter the performance and cost of media filtration. Compared to conventional sand or multimedia filtration beds, the main advantages are as follows:

- Superior filtration performance

- Higher flow capacity

- Higher dirt holding capacity

- Reduced backwash time and frequency

- Lower capital cost

- Long lasting media

Next-Sand™ is suitable for use in vertical or horizontal vessels and pressure or gravity feed systems. It, therefore, can be used in a broad range of applications in the water and wastewater industry.

Next-Sand™ Applications:

- Reverse osmosis pretreatment with superior silt density index (SDI) reduction

- Cooling towers with unequalled turbidity removal

- Municipal water treatment, pressure and gravity filters with higher flow, low pressure drop and superior filtration performance

- Desalination plants

- Swimming pool and spa filtration with high ammonia removal

- Wastewater polishing with exceptional total suspended solids (TSS) removal

- Precipitated metals removal

- Carwash reclaim and recycling

- Irrigation

- Paper mill filtration

- Aquaria and aquaculture

- Surface water, wastewater, seawater, and ground water: any water treatment application!

Next-Sand™ is NSF/ANSI 61 and BS6920 certified and complies to EU draft standard pr EN16070 for drinking water.

Physical properties as follows:

- Composition: High-Purity Alumino-Silicate (Clinoptilolite)

- Size: 0.4-1.4mm (Approx 14×40 mesh)

- Color: Dark Grey

- Surface Area: 25m²/gram

- Surface Absorption: Hydrophilic

- Thermal Stability: Stable up to 500˚C

- Coeffficient of Uniformity: 1.7

- Bed Void Volume: 55%

- Surface Charge: Net Negative